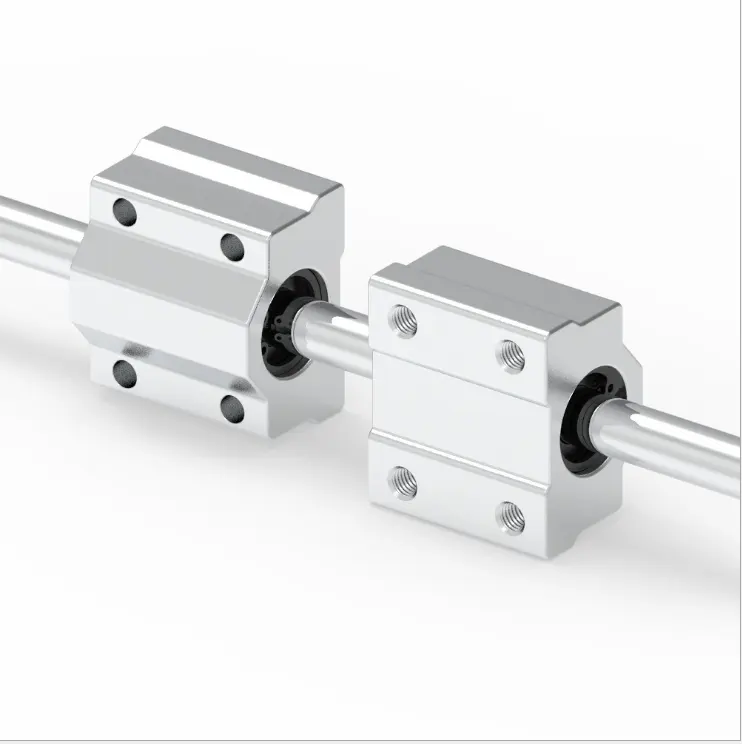

Improvement of Heavy Machinery Operation with Sliding Bearings

Sliding bearings play a crucial role in enhancing the operation of heavy machinery, such as mining equipment. Here’s how they contribute:

Reduced Friction and Wear:

Sliding bearings are designed to minimize friction between moving parts. In heavy machinery, where components are subjected to substantial loads and harsh conditions, reducing friction is essential to prevent premature wear and damage. Sliding bearings help distribute loads evenly and provide a smooth surface for components to slide against, reducing the risk of friction-induced failures.

Increased Durability:

The robust construction and materials used in sliding bearings make them well-suited for heavy machinery applications. They can withstand the heavy loads, impacts, and vibrations commonly encountered in mining equipment. Their durability contributes to the overall reliability and longevity of the machinery.

Improved Efficiency:

Efficiency is critical in heavy machinery to maximize productivity while minimizing energy consumption. Sliding bearings contribute to improved efficiency by reducing energy losses due to friction. With lower friction, machinery components can move more freely, requiring less energy to overcome resistance.

Resistance to Contaminants:

Mining environments are often filled with dust, dirt, and debris that can infiltrate machinery components. Sliding bearings are designed to operate effectively even in contaminated conditions. Their design and materials help prevent the intrusion of contaminants, reducing the risk of premature wear and component failure.

Enhanced Load Distribution:

Heavy machinery, especially in mining, experiences dynamic and uneven loads. Sliding bearings help distribute these loads evenly across surfaces, preventing localized stress concentrations. This load distribution contributes to the machinery’s overall structural integrity and minimizes the risk of catastrophic failures.

In conclusion, sliding bearings are integral to the efficient and reliable operation of heavy machinery in industries like mining. Their ability to reduce friction, enhance durability, improve efficiency, resist contaminants, and distribute loads makes them invaluable components for ensuring the smooth functioning of mining equipment.

Benefits of Sliding Bearings in Low-Speed and Heavy-Load Applications

Sliding bearings offer significant advantages in low-speed and heavy-load applications, where their unique characteristics provide optimal performance. Some examples of scenarios where sliding bearings benefit such applications include:

- Mining Equipment: Sliding bearings are used in mining machinery such as crushers, mills, and conveyor systems. These applications often involve heavy loads and low speeds, where sliding bearings can provide robust support and reliable operation.

- Steel Mills: In steel production, sliding bearings are utilized in rolling mills and continuous casting machines. These operations require handling heavy loads and slow rotation speeds, making sliding bearings suitable for providing the necessary support.

- Hydraulic Systems: Sliding bearings are used in hydraulic cylinders, where slow and controlled movements are required for applications like construction machinery, material handling equipment, and heavy-duty presses.

- Cranes and Lifts: Sliding bearings are employed in the construction of cranes, elevators, and lifting platforms. These applications involve lifting and lowering heavy loads at controlled speeds, making sliding bearings crucial for smooth and reliable motion.

- Wind Turbines: Sliding bearings are used in the yaw and pitch systems of wind turbines. These systems need to handle the substantial weight of the turbine blades and operate at low speeds to optimize energy generation.

In these scenarios and more, sliding bearings provide the necessary support, stability, and durability required for low-speed and heavy-load applications.

Common Applications and Industries of Sliding Bearings

Sliding bearings are utilized across a wide range of applications and industries due to their unique advantages. Some common applications and industries where sliding bearings are commonly used include:

- Automotive Industry: Sliding bearings are found in engines, transmissions, suspension systems, and various automotive components.

- Industrial Machinery: They are used in manufacturing equipment, conveyors, printing machines, and more.

- Power Generation: Sliding bearings are crucial in turbines, generators, and power transmission systems.

- Aerospace: They play a role in aircraft landing gear, control systems, and propulsion mechanisms.

- Marine: Sliding bearings are used in ship engines, propellers, and steering systems.

- Construction and Mining: They are found in heavy machinery, excavators, loaders, and construction equipment.

- Oil and Gas: Sliding bearings are used in drilling rigs, pumps, compressors, and refineries.

- Railway: They are employed in locomotives, train wheels, and rail systems.

- Medical Equipment: Sliding bearings are used in medical devices, imaging equipment, and surgical instruments.

- Textile Industry: They play a role in weaving machines, spinning frames, and looms.

- Food and Beverage: Sliding bearings are utilized in food processing equipment and packaging machinery.

- Renewable Energy: They are used in wind turbines, solar tracking systems, and other renewable energy applications.

Sliding bearings provide reliable support and smooth motion in various environments, making them essential components in a wide range of industries.

editor by CX 2024-04-16