Product Description

HangZhou CZPT PULLEY MANUFACTURE CO., LTD. has been specialized in manufacturing Plastic Pulley/Rollers, Die-punching Pulley/Bearing, and Non-standard Bearings for about 25 years. It is located in HangZhou city of ZHangZhoug Province, which has convenient transportation benefited from Nignbo Seaport, HangZhou International Airport and the highway networks. Our company covers an area of 7000 m², with building area of 10500 m². Relying on advanced processing equipments and technology, and strict inspection system, our company is CZPT to provide good-quality and competitive products, and has gained a good reputation among customers.

We are committed to developing and designing different kinds of non-standard pulley bearings, with an annual production capacity of 120 million sets. We export to more than 70 countries and areas, like USA, Canada, Spain, Germany, France and Italy, etc.

Our company maintains our quality system to ISO 9001:2000, and has been audited by SGS for our production operations. We will continuously seek to provide our customers with good-quality products, excellent service and most competitive price. We look forward to building long-term business relationship with you and achieving our mutual benefits.

About us

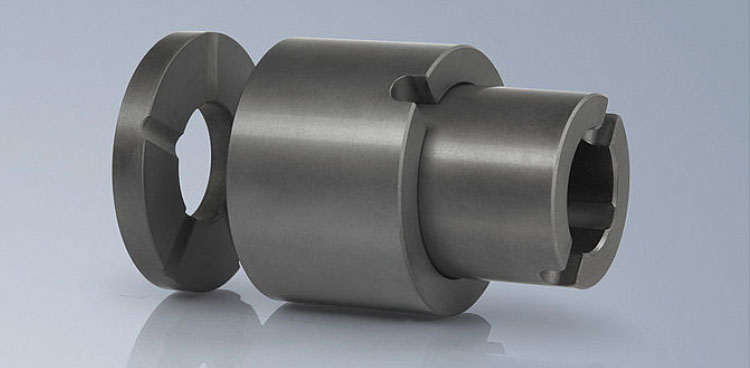

| name | Stable Plastic Bearing with Steel Balls Sliding Bearing Roller with ROHS(ML-AU043) |

| Brand name | According to customers’ requirements |

| Size | As per the customer’s technic drawing or samples |

| material | pom,pa6,pa66,nylon,pvc,abs…wheels,Aluminium,Zinc,Stainless steel frame |

| Technical process | bearing production assembling,zinc plating,injection,turning |

| Color | orange,white,black,yellow |

| Types | customized |

| Payment terms | A:100% TT B: 30% T/T in advance .70% against copy of B/L |

| Application | caster wheel , small pulley , window , sliding door ,door closet wardrobe system… |

| Product Description | 1.Item No.: as shown in the picture. 2.Material: steel/zinc/aluminum/plastic bracket + ball bearing / needle bearing wheel 3.For some models, the height of the roller is adjustable. 4.Color of the wheel: red, green, white, orange, etc. 5.Application: sliding door and window, binds, rolling shutters, furniture, conveyor belt, etc. 6.Normal packing: poly bag + outer carton |

Contact Us

HangZhou CZPT Pulley Manufacture Co., Ltd.

WEB: http://nbminli /

ADDRESS: No.9 CZPT Road, CZPT Industrial Zone, Xihu (West Lake) Dis. District, HangZhou, China

Comparable products

FAQ

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a quotaion in the shortest time?

A: When you send us an enquiry, please try to provide more details, such as product size, photo or drawing, order quantity, etc.

Q: How to start an OEM project with your company?

A: Please send us your designed drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange sample production once received your deposit .

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. Nomally our company MOQ is 10000pc , but it can be much more or less depending on different product types. Therefore, we recommend you to tell us your required quantity first.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. The lead time varies from 30 to 90 days.

Why choose us

1.Professional experience: almost 20 years’ expenience in non-standard bearings, rollers, pulleys, and other plastic accessories for door and window.

2.Popular over the world: over 20 market countries.

3.Advantage: good quality with competitive price.

4.OEM offered: technical drawings, samples or photos are needed.

For more information, please visit http://nbminli /

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Micro(≤26mm) |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Sliding Bearings to Agricultural Machinery and Equipment

Sliding bearings play a crucial role in enhancing the functionality and efficiency of various agricultural machinery and equipment. Here’s how they contribute:

Smooth Movement: Sliding bearings provide smooth and low-friction movement in agricultural machinery, ensuring efficient operation of components like pivots, linkages, and joints.

Load Distribution: Sliding bearings distribute loads evenly across surfaces, reducing stress on components and extending the lifespan of agricultural equipment.

Durability: Sliding bearings are designed to withstand harsh conditions commonly encountered in agriculture, such as exposure to dirt, debris, and moisture.

Low Maintenance: Sliding bearings require minimal maintenance due to their self-lubricating properties, reducing downtime and operational costs.

Vibration Dampening: Sliding bearings help dampen vibrations in agricultural machinery, improving operator comfort and reducing wear on components.

Enhanced Precision: Sliding bearings ensure precise movement in equipment like planting and harvesting machinery, contributing to accurate and consistent operations.

Versatility: Sliding bearings are used in a wide range of agricultural applications, including tractors, combines, plows, irrigation systems, and more.

Cost Efficiency: Sliding bearings provide a cost-effective solution for agricultural machinery, offering long service life and reducing the need for frequent replacements.

Reliability: Sliding bearings offer reliable performance even in challenging agricultural environments, contributing to the overall reliability of the equipment.

Environmental Adaptability: Sliding bearings can handle varying weather conditions and exposure to agricultural chemicals without compromising performance.

Overall, sliding bearings play a vital role in ensuring the smooth operation, durability, and performance of agricultural machinery and equipment, contributing to increased productivity and reduced maintenance requirements in the agriculture sector.

Signs of Wear or Damage in Sliding Bearings and Replacement Timing

Recognizing signs of wear or damage in sliding bearings is crucial for maintaining the performance and integrity of machinery and equipment. Here are the common signs to look for and the appropriate timing for replacement:

Increased Friction and Heat: If you notice higher levels of friction or heat around the bearing area, it could indicate that the bearing surfaces are experiencing excessive wear. Over time, this can lead to reduced efficiency and potentially cause further damage to the bearing and surrounding components.

Abnormal Noise: Unusual noises, such as grinding, squeaking, or knocking sounds, can indicate wear or damage within the sliding bearings. These noises are often caused by metal-to-metal contact or irregular movement of the bearing surfaces.

Uneven Wear Patterns: Inspect the bearing surfaces for uneven wear patterns, pitting, or scoring. These signs suggest that the bearing is not distributing the load properly, leading to localized damage and reduced performance.

Reduced Performance: If you notice a decline in the overall performance of the machinery or equipment, such as decreased output, slower operation, or reduced precision, it could be due to compromised sliding bearings.

Excessive Vibration: Excessive vibration can be a result of misaligned or damaged sliding bearings. Vibrations can affect the stability of the machinery and lead to premature wear of other components.

Visible Debris or Contamination: If you observe signs of debris, contaminants, or metal particles in the lubricant or around the bearing area, it could indicate wear or damage. Contaminants can accelerate wear and cause abrasive damage to the bearing surfaces.

Leakage of Lubricant: Sliding bearings often require proper lubrication to function effectively. If you notice a significant amount of lubricant leakage or seepage, it might be a sign that the bearing seals are compromised, which can lead to inadequate lubrication and accelerated wear.

Replacement Timing: It’s essential to replace sliding bearings as soon as signs of wear or damage are detected. Delaying replacement can lead to further deterioration, increased downtime, and potential damage to other components. Regular maintenance and inspections can help catch these issues early and prevent costly breakdowns.

Overall, monitoring the condition of sliding bearings through routine inspections and addressing signs of wear promptly can help ensure the longevity, efficiency, and reliability of machinery and equipment.

Considerations for Selecting Sliding Bearings

When choosing a sliding bearing for a specific application, several key factors should be taken into consideration:

- Load Capacity: Determine the maximum load the bearing will need to support. This includes both radial and axial loads, as well as any dynamic or static loads.

- Operating Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants. Different materials and coatings may be required for harsh conditions.

- Lubrication: Choose the appropriate lubrication method based on the application. Consider factors such as the frequency of lubrication, the availability of lubrication points, and the compatibility of lubricants with the bearing material.

- Speed and Motion: Evaluate the speed and type of motion the bearing will experience. Higher speeds may require special considerations for heat dissipation and lubrication.

- Alignment and Misalignment: Determine if the bearing will need to accommodate misalignment between the shaft and the bearing housing. Some applications may require self-aligning or spherical bearings.

- Wear Resistance: Choose a bearing material that offers good wear resistance to prevent premature wear and extend the bearing’s lifespan.

- Noise and Vibration: Consider the impact of noise and vibration on the application. Bearings with proper damping properties can help reduce noise and vibration levels.

- Maintenance Requirements: Assess the ease of maintenance, including lubrication intervals, accessibility of lubrication points, and the need for regular inspections.

- Cost and Availability: Compare the cost of the bearing with its expected performance and lifespan. Also, ensure that the chosen bearing type and size are readily available.

- Application-Specific Considerations: Some applications may have unique requirements, such as corrosion resistance, electrical insulation, or compatibility with food-grade standards.

By carefully considering these factors, you can select a sliding bearing that meets the specific needs of your application, ensuring reliable performance and longevity.

editor by CX 2024-04-30