Product Description

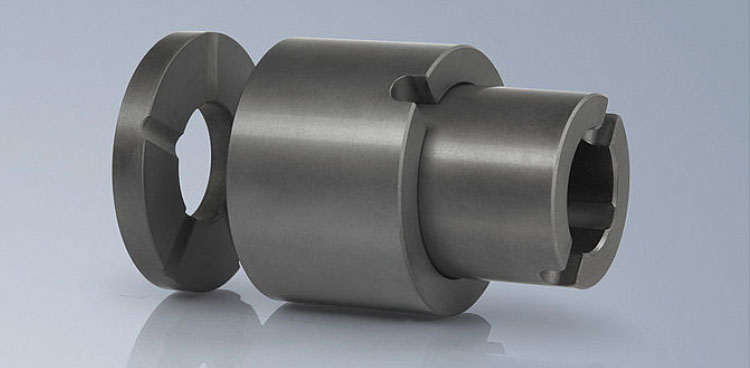

Latest design Aluminum Door Sliding Window Roller Bearing 10*30*9 V3*1.5 6200Z

Introduction

This bearing is custom-designed for bearing steel, dimensional accuracy are very good, suitable for high-precision, high-speed, high-load components.

This roller mainly used for wire cutting molybdenum wire and other wire CZPT wheel CZPT wheel assembly. Please confirm the purchase.

Different shapes of materials are suitable for the straightening wheel groove type, the linear type is suitable for V groove, the bar material is suitable for U groove, and the rectangular flat material is suitable for H groove.

We offer customed service according to your drawing.

Customizable, please contact customer service!!!

Model description

Model description

10*30*9 V3*1.5 represents inner diameter 10mm* outer diameter 30mm* height 9mm, V3*1.5 represents V groove, groove width 3mm, groove depth 1.5mm

Other Mordels

| Inner diameter | outer diameter | height | Groove | Inner diameter*outer diameter*height(mm) | Type |

| 3 | 10 | 3 | U/V/H | 3*10*3 | |

| 3 | 12 | 4 | U/V/H | 3*12*4 | |

| 4 | 10 | 4 | U/V/H | 4*10*4 | |

| 4 | 11 | 4 | U/V/H | 4*11*4 | |

| 4 | 12 | 4 | U/V/H | 4*12*4 | |

| 4 | 13 | 4 | U/V/H | 4*13*4 | |

| 4 | 13 | 5 | U/V/H | 4*13*5 | 624Z |

| 4 | 13 | 6 | U/V/H | 4*13*6 | |

| 4 | 13 | 7 | U/V/H | 4*13*7 | |

| 4 | 18 | 7 | U/V/H | 4*18*7 | V1804RS |

| 6 | 12 | 4 | U/V/H | 6*12*4 | |

| 6 | 13 | 5 | U/V/H | 6*13*5 | |

| 6 | 15 | 6 | U/V/H | 6*15*6 | |

| 6 | 17 | 6 | U/V/H | 6*17*6 | |

| 6 | 19 | 6 | U/V/H | 6*19*6 | |

| 6 | 19 | 9 | U/V/H | 6*19*9 | |

| 6 | 20 | 6 | U/V/H | 6*20*6 | |

| 6 | 20 | 9 | U/V/H | 6*20*9 | |

| 6 | 20 | 10 | U/V/H | 6*20*10 | |

| 6 | 21 | 6 | U/V/H | 6*21*6 | |

| 6 | 22 | 7 | U/V/H | 6*22*7 | |

| 6 | 22 | 11 | U/V/H | 6*22*11 | |

| 6 | 24 | 11 | U/V/H | 6*24*11 | SG20 |

| 6 | 27 | 6 | U/V/H | 6*27*6 | |

| 6 | 27 | 8 | U/V/H | 6*27*8 | |

| 6 | 28 | 7 | U/V/H | 6*28*7 | |

| 8 | 22 | 7 | U/V/H | 8*22*7 | 608Z |

| 8 | 24 | 8 | U/V/H | 8*24*8 | |

| 8 | 24 | 11 | U/V/H | 8*24*11 | |

| 8 | 26 | 7 | U/V/H | 8*26*7 | |

| 8 | 28 | 9 | U/V/H | 8*28*9 | |

| 8 | 37 | 11 | U/V/H | 8*37*11 | |

| 8 | 40 | 12 14 | U/V/H | 8*40*12/14 | SG20 |

| 10 | 27 | 14 | U/V/H | 10*27*14 | |

| 10 | 30 | 8 | U/V/H | 10*30*8 | |

| 10 | 30 | 9 | U/V/H | 10*30*9 | 6200Z |

| 10 | 30 | 13 | U/V/H | 10*30*13 | |

| 10 | 32 | 9 | U/V/H | 10*32*9 | 6202Z |

| 10 | 32 | 14 | U/V/H | 10*32*14 | 629 2RS |

| 10 | 35 | 9 | U/V/H | 10*35*9 | SG20 |

| 10 | 35 | 11 | U/V/H | 10*35*11 | |

| 10 | 37 | 12 | U/V/H | 10*37*12 | |

| 10 | 40 | 14 | U/V/H | 10*40*14 | |

| 10 | 46 | 16 | U/V/H | 10*46*16 | |

| 12 | 32 | 10 | U/V/H | 12*32*10 | |

| 12 | 37 | 12 | U/V/H | 12*37*12 | |

| 12 | 42 | 19 | U/V/H | 12*42*19 | 629 2RS |

| 12 | 45 | 24 | U/V/H | 12*45*24 | |

| 12 | 54 | 25 | U/V/H | 12*54*25 | 629 2RS |

| 12 | 50 | 13 | U/V/H | 12*50*13 | |

| 15 | 47 | 11 | U/V/H | 15*47*11 | 6202Z |

Certifications

Company Profile

Who are we?

Q1: Are you a factory or trading company?

We are a factory . We can promise you a short lead time and best price if you purchase our machine. We also have our own trading department.

Q2: How does the factory ensure products quality?

With Nearly 16 years experience in manufacturing winding machine, we have our own technology develop department and testing department.

Quality is the first priority. We have strict purchasing system to ensure the quality of spare parts. We have experienced workers to assemble and test machine.

Q3:How about your after-sale service?

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone, webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

Q4: What are your payment terms?

100%TT or prepaid 50% , balance 50% before shipping.

Q5: How can I get my order? How can I know you sent the goods?

We will send the goods by UPS, DHL, FedEx or sea shipment. After we sent the goods, we will give you the tracking number or other relative files for checking.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Spherical: | Aligning Bearings |

| Load Direction: | Axial Bearing |

| Separated: | Unseparated |

| Customization: |

Available

| Customized Request |

|---|

Challenges of Lubricant Contamination in Sliding Bearings and Solutions

Lubricant contamination in sliding bearings can lead to various challenges that impact performance and longevity. Here are some challenges and solutions:

Challenge: Reduced Lubrication Effectiveness

Contaminants such as dust, dirt, moisture, and foreign particles can compromise the lubricant’s ability to provide effective lubrication between bearing surfaces.

Solution: Regular maintenance practices involving cleaning and relubrication help remove contaminants and restore the lubricant’s effectiveness. Proper seals and shields can also prevent contaminants from entering the bearing.

Challenge: Increased Friction and Wear

Contaminants in the lubricant can create abrasive particles that increase friction and accelerate wear on bearing surfaces.

Solution: Using high-quality, clean lubricants and implementing effective filtration systems can minimize the presence of contaminants, reducing friction and wear.

Challenge: Component Damage

Contaminants can cause pitting, scratching, and other damage to bearing surfaces, leading to decreased performance and potential bearing failure.

Solution: Regular inspections and cleaning routines are essential to prevent the accumulation of contaminants. Using lubricants with appropriate viscosity and additives can also help protect bearing surfaces.

Challenge: Increased Heat and Temperature

Contaminants can create heat and increase operating temperatures due to increased friction, which can negatively impact bearing performance.

Solution: Clean lubricants with proper viscosity and thermal stability are essential to dissipate heat effectively. Maintaining proper lubrication levels helps manage temperature rise.

Challenge: Corrosion

Moisture and certain contaminants can lead to corrosion of bearing surfaces, which compromises their structural integrity.

Solution: Proper storage and handling of bearings, as well as using corrosion-resistant lubricants, can mitigate the risk of corrosion. Seals and shields also provide additional protection against moisture ingress.

Challenge: Lubricant Breakdown

Contaminants and high operating temperatures can cause lubricants to degrade over time, reducing their lubricating properties.

Solution: Monitoring lubricant condition and replenishing or changing it at appropriate intervals helps maintain its effectiveness. Using lubricants with good oxidation resistance is also important.

Lubricant contamination in sliding bearings can significantly impact their performance and longevity. Implementing proper maintenance practices, using clean and suitable lubricants, and employing effective sealing mechanisms are key strategies to address these challenges and ensure optimal sliding bearing operation.

Maintenance Practices to Extend the Lifespan of Sliding Bearings

Proper maintenance is essential for maximizing the lifespan of sliding bearings and ensuring optimal performance. Here are specific practices that can help extend the life of sliding bearings:

Regular Lubrication: Adequate lubrication is crucial for minimizing friction and wear between sliding surfaces. Follow manufacturer recommendations for lubrication intervals and use the appropriate lubricants for the operating conditions.

Clean Environment: Keep the surrounding environment clean and free from dust, dirt, and contaminants. Regularly clean the machinery or equipment to prevent debris from entering the bearing area.

Seal Integrity: Ensure that bearing seals are in good condition to prevent contaminants from entering and lubricant from escaping. Replace damaged seals promptly to maintain proper protection.

Alignment and Mounting: Proper alignment and mounting of sliding bearings are critical to distribute loads evenly and prevent excessive wear. Follow manufacturer guidelines for installation procedures and torque specifications.

Regular Inspections: Schedule routine inspections to detect early signs of wear, damage, or misalignment. Visual inspections, temperature checks, and vibration analysis can help identify issues before they escalate.

Maintenance Records: Maintain detailed records of maintenance activities, including lubrication schedules, inspections, and replacements. This information can help track the condition of sliding bearings and plan maintenance tasks effectively.

Temperature Management: Control operating temperatures within recommended limits. Excessive heat can degrade lubricants and accelerate wear, while extreme cold can affect bearing performance.

Load Management: Avoid subjecting sliding bearings to loads beyond their specified capacities. Overloading can lead to premature wear and damage.

Training and Education: Ensure that personnel responsible for maintenance are adequately trained in proper procedures. Knowledgeable staff can perform maintenance tasks accurately and identify potential issues.

Timely Replacement: When wear or damage is detected that exceeds acceptable limits, replace sliding bearings promptly to prevent further damage to the machinery or equipment.

By implementing these maintenance practices, you can significantly extend the lifespan of sliding bearings, reduce downtime, and optimize the performance of machinery and equipment.

Impact of Proper Lubrication on Sliding Bearings

Proper lubrication plays a critical role in the performance and longevity of sliding bearings. Here’s how it affects their operation:

- Reduced Friction and Wear: Lubrication forms a thin film between the sliding surfaces of the bearing, reducing direct metal-to-metal contact. This minimizes friction and wear, which can significantly extend the bearing’s lifespan.

- Heat Dissipation: Lubricants help dissipate heat generated during operation by carrying away excess heat from the friction zones. This prevents overheating and potential damage to the bearing and surrounding components.

- Corrosion Prevention: Lubricants provide a protective barrier against moisture and corrosive substances, preventing the formation of rust and corrosion on the bearing surfaces.

- Sealing Effect: Proper lubrication can help create a sealing effect that prevents contaminants from entering the bearing, maintaining a clean and efficient operating environment.

- Noise and Vibration Reduction: Adequate lubrication helps dampen noise and reduce vibration caused by friction between bearing surfaces. This contributes to quieter and smoother operation.

- Enhanced Load Distribution: Lubrication ensures even load distribution across the bearing surfaces, preventing localized wear and extending the bearing’s overall life.

- Stability and Performance: Proper lubrication maintains consistent performance and stability by minimizing variations in friction and reducing the risk of sudden failures.

- Seizure Prevention: Lubricants prevent sliding surfaces from seizing or sticking together, even during periods of prolonged inactivity.

- Optimized Efficiency: Well-lubricated bearings experience less energy loss due to friction, resulting in improved overall efficiency of the machinery.

Choosing the right lubricant type, viscosity, and lubrication interval is crucial to ensuring the optimal performance and durability of sliding bearings. Regular maintenance and monitoring of lubrication levels are essential to prevent issues and extend the bearing’s service life.

editor by CX 2024-05-08