Product Description

Product Description

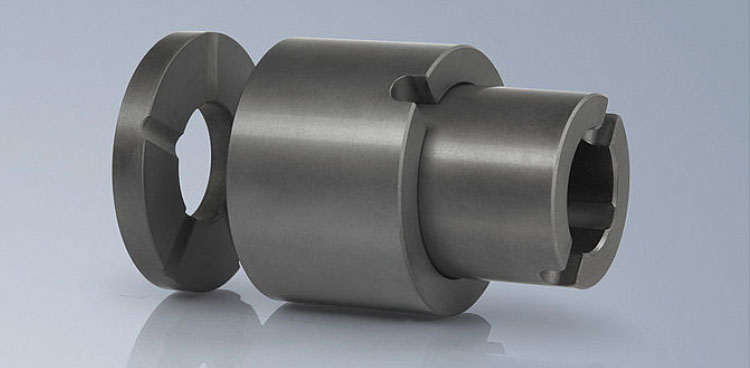

Building upon on the foundation of spherical bearings, sliding spherical bearings incorporate additional flat sliding surfaces.

Similar to spherical bearings, sliding spherical bearings are capable of withstanding vertical, horizontal and tension loads while providing rotational capabilities in all directions. Additionally, they offer horizontal movement capabilities.

This product is in compliance with the following standards:

- “Spherical bearings for steel building structure” GB/T 32836-2016

- “Spherical bearings for bridges” GB/T 17955-2009

Detailed Photos

Product Parameters

Packaging & Shipping

Company Profile

ZheJiang Ansha New Material Technology Co., Ltd. is located in Xihu (West Lake) Dis. New District of HangZhou City. We specialize in R&D and production of seismic isolation and damping products for both buildings and bridges. Our products include rubber bearings, spherical bearings, friction pendulum systems, fluid viscous dampers, tuned mass dampers, buckling-restrained braces, friction dampers and metallic dampers. In addition, we manufacture bridge expansion joints and fiber-enhanced plastic products.

We have established state-of-the-art physical and chemical laboratories and specialized production lines. Our company operates in full compliance with the ISO9001:2015 Quality Management System, ISO14001:2015 Environmental Management System, and ISO45001:2018 Occupational CZPT and Safety Management System.

Xihu (West Lake) Dis.d by the anti-seismic design principle of “resisting collapse in a major earthquake, enabling repair in a moderate earthquake, and remaining undamaged in a minor earthquake”, we offer our customers a comprehensive array of services. These services include technical consultation, structural analysis and calculation, design optimization, research and development, manufacturing, installation guidance, performance monitoring, maintenance and repair.

Our Advantages

1. Advanced equipment. Our workshop has more than 100 pieces of the most advanced equipment to ensure timely delivery of large orders. In addition, standardized production can be guaranteed to comply with international standards.

2. Experienced and skilled technical and production teams have professional production skills and many years of experience. Our team of workers can improve production efficiency, shorten the production cycle, and thereby reduce costs.

3. Complete product models, we have a variety of bearings for construction, including basin bearings, elastic skateboard bearings, spherical bridge bearings, high damping spherical bearings, lead rubber bearings, etc.

4. Exquisite packaging and timely delivery. All products are inspected by quality inspection personnel before loading, and then the quality inspection data are archived and retained. Our company also produces isolation products and vibration control products.

5. The professional sales team has a comprehensive understanding of shock absorption and isolation products, good English speaking and writing skills, and excellent communication skills to provide the best solutions to your problems. You can ask them for recommendations, customized services, and any other product information you want to know about.

FAQ

1. Are you a trading company or manufacturer?

We are manufacturer and have our own factory

2. What certificate do you get?

ISO9001:2015 quality management system certification,

ISO14001:2015 environmental management system certification,

ISO45001:2018 occupational CZPT and safety management system certification

3. What is your MOQ?

2 Sets

4. What is your delivery time for mass production?

Customized product design time: Based on the performance parameters provided, the detailed design of the product will be completed within 7 working days

Peak season delivery time: 1.5~2 months after confirmation of product processing drawings

Off-season delivery time: Within 25~35 working days after confirmation of product processing drawings

5. Can you do OEM?

We can. OEM orders are welcome.

6. What is your policy sample?

We provide free scale samples, and buyers bear the express delivery costs.

7. How long does it take to prepare samples?

About 7-10 working days.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Installation Guide |

|---|---|

| Warranty: | 1-3 Years |

| Certification: | DIN, JIS, GB, BS, ASTM, AISI |

| Usage: | Beam Bridge, Highway Bridge, Railroad Bridge |

| Structure: | Spherical Steel Bearing |

| Material: | Steel Bearing |

| Samples: |

US$ 300/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Challenges of Lubricant Contamination in Sliding Bearings and Solutions

Lubricant contamination in sliding bearings can lead to various challenges that impact performance and longevity. Here are some challenges and solutions:

Challenge: Reduced Lubrication Effectiveness

Contaminants such as dust, dirt, moisture, and foreign particles can compromise the lubricant’s ability to provide effective lubrication between bearing surfaces.

Solution: Regular maintenance practices involving cleaning and relubrication help remove contaminants and restore the lubricant’s effectiveness. Proper seals and shields can also prevent contaminants from entering the bearing.

Challenge: Increased Friction and Wear

Contaminants in the lubricant can create abrasive particles that increase friction and accelerate wear on bearing surfaces.

Solution: Using high-quality, clean lubricants and implementing effective filtration systems can minimize the presence of contaminants, reducing friction and wear.

Challenge: Component Damage

Contaminants can cause pitting, scratching, and other damage to bearing surfaces, leading to decreased performance and potential bearing failure.

Solution: Regular inspections and cleaning routines are essential to prevent the accumulation of contaminants. Using lubricants with appropriate viscosity and additives can also help protect bearing surfaces.

Challenge: Increased Heat and Temperature

Contaminants can create heat and increase operating temperatures due to increased friction, which can negatively impact bearing performance.

Solution: Clean lubricants with proper viscosity and thermal stability are essential to dissipate heat effectively. Maintaining proper lubrication levels helps manage temperature rise.

Challenge: Corrosion

Moisture and certain contaminants can lead to corrosion of bearing surfaces, which compromises their structural integrity.

Solution: Proper storage and handling of bearings, as well as using corrosion-resistant lubricants, can mitigate the risk of corrosion. Seals and shields also provide additional protection against moisture ingress.

Challenge: Lubricant Breakdown

Contaminants and high operating temperatures can cause lubricants to degrade over time, reducing their lubricating properties.

Solution: Monitoring lubricant condition and replenishing or changing it at appropriate intervals helps maintain its effectiveness. Using lubricants with good oxidation resistance is also important.

Lubricant contamination in sliding bearings can significantly impact their performance and longevity. Implementing proper maintenance practices, using clean and suitable lubricants, and employing effective sealing mechanisms are key strategies to address these challenges and ensure optimal sliding bearing operation.

Enhancing Efficiency of Marine Propulsion Systems with Sliding Bearings

Sliding bearings play a crucial role in enhancing the efficiency of marine propulsion systems and various ship components. Here’s how sliding bearings contribute to the efficiency of maritime applications:

Reduced Friction: Sliding bearings are designed to minimize friction between moving parts. In marine propulsion systems, such as propeller shafts and stern tubes, reduced friction results in less energy loss and improved fuel efficiency.

Smooth Operation: Sliding bearings provide smooth and controlled movement of rotating or linear components. In marine applications, this smooth operation translates to improved maneuverability, reduced vibrations, and enhanced overall performance.

Load Distribution: Sliding bearings distribute loads evenly across bearing surfaces. This even distribution helps prevent localized wear and reduces the risk of premature failure, ensuring reliable operation of ship components.

Resistance to Harsh Environments: Marine environments expose equipment to corrosive saltwater, extreme temperatures, and harsh weather conditions. Sliding bearings are often designed with materials and coatings that offer corrosion resistance and durability, ensuring longevity even in challenging maritime settings.

Enhanced Lubrication: Lubrication is vital for reducing wear and friction in sliding bearings. Many marine applications use advanced lubrication systems that optimize the distribution of lubricants, further reducing friction and improving efficiency.

Space Efficiency: Sliding bearings are compact and require minimal space, making them suitable for marine systems where space is limited. This efficient use of space is particularly important in ship design and layout.

Customization for Specific Needs: Sliding bearings can be tailored to meet the specific requirements of different ship components. This customization ensures that bearings are optimized for their intended functions, further contributing to efficiency.

Reduced Maintenance: Properly designed sliding bearings require less maintenance compared to some other types of bearings. This reduced maintenance need translates to less downtime and increased operational efficiency for marine vessels.

Optimized Performance: Overall, the efficient and reliable performance of sliding bearings in marine propulsion systems and ship components leads to improved energy efficiency, reduced operational costs, and extended service life of the equipment.

By incorporating sliding bearings into marine applications, shipbuilders and operators can achieve enhanced efficiency, reliability, and sustainability in their operations.

Considerations for Selecting Sliding Bearings

When choosing a sliding bearing for a specific application, several key factors should be taken into consideration:

- Load Capacity: Determine the maximum load the bearing will need to support. This includes both radial and axial loads, as well as any dynamic or static loads.

- Operating Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants. Different materials and coatings may be required for harsh conditions.

- Lubrication: Choose the appropriate lubrication method based on the application. Consider factors such as the frequency of lubrication, the availability of lubrication points, and the compatibility of lubricants with the bearing material.

- Speed and Motion: Evaluate the speed and type of motion the bearing will experience. Higher speeds may require special considerations for heat dissipation and lubrication.

- Alignment and Misalignment: Determine if the bearing will need to accommodate misalignment between the shaft and the bearing housing. Some applications may require self-aligning or spherical bearings.

- Wear Resistance: Choose a bearing material that offers good wear resistance to prevent premature wear and extend the bearing’s lifespan.

- Noise and Vibration: Consider the impact of noise and vibration on the application. Bearings with proper damping properties can help reduce noise and vibration levels.

- Maintenance Requirements: Assess the ease of maintenance, including lubrication intervals, accessibility of lubrication points, and the need for regular inspections.

- Cost and Availability: Compare the cost of the bearing with its expected performance and lifespan. Also, ensure that the chosen bearing type and size are readily available.

- Application-Specific Considerations: Some applications may have unique requirements, such as corrosion resistance, electrical insulation, or compatibility with food-grade standards.

By carefully considering these factors, you can select a sliding bearing that meets the specific needs of your application, ensuring reliable performance and longevity.

editor by CX 2024-05-07