Product Description

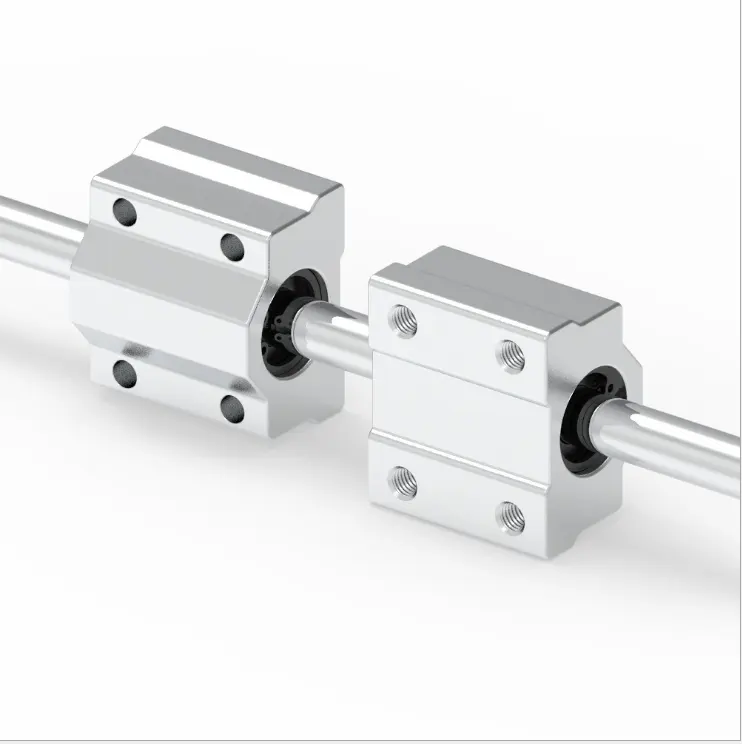

Linear Motion Slide Sliding Bearing Lmb16uu Lmb16luu Lm16 Outlet linear motion ball bearing

Product Description

Linear bearings are used with hardened linear drive shafts. A system for infinite linear motion. Because the load ball and the quenching drive shaft are in point contact, the allowable load is small, but when moving in a straight line, the friction resistance is the smallest, the precision is high, and the movement is fast.

(1) Standard type, clearance adjustment type linear bearing, open type linear bearing, extended type linear bearing, general type linear bearing

(2) Flanged linear bearings can be divided into: round flange type, square flange type, oval flange type, CZPT round flange type, CZPT square flange type, CZPT oval flange type, and elongated round flange type.

Linear bearings are more and more widely used in electronic equipment, food machinery, packaging machinery, medical machinery, printing machinery, textile machinery, machinery, instruments, robots, tool machinery, CNC machine tools, automobiles and digital 3D coordinate measuring equipment and other precision equipment or special machinery industry.

|

Bearing NO. |

Inner diameter (mm) |

External diameter (mm) |

Length (mm) |

|

LM3 UU |

3 |

7 |

10 |

|

LM4 UU |

4 |

8 |

12 |

|

LM5 UU |

5 |

10 |

15 |

|

LM6 UU |

6 |

12 |

19 |

|

LM8 SUU |

8 |

15 |

17 |

|

LM8 UU |

8 |

15 |

24 |

|

LM10 UU |

10 |

19 |

29 |

|

LM12 UU |

12 |

21 |

30 |

|

LM13 UU |

13 |

23 |

32 |

|

LM16 UU |

16 |

28 |

37 |

|

LM20 UU |

20 |

32 |

42 |

|

LM25 UU |

25 |

40 |

59 |

|

LM30 UU |

30 |

45 |

64 |

|

LM35 UU |

35 |

52 |

70 |

|

LM40 UU |

40 |

60 |

80 |

|

LM50 UU |

50 |

80 |

100 |

|

LM60 UU |

60 |

90 |

110 |

|

LM80 UU |

80 |

120 |

140 |

|

LB81625 |

8 |

16 |

25 |

Detailed Photos

Certifications

Packaging & Shipping

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Vacuum, Magnetically, High Temperature |

|---|---|

| Function: | Super |

| Flange Shape: | Square |

| Shape: | Open |

| Series: | LM |

| Material: | Gcr15, Ss, High Carbon Steel |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Improvement of Heavy Machinery Operation with Sliding Bearings

Sliding bearings play a crucial role in enhancing the operation of heavy machinery, such as mining equipment. Here’s how they contribute:

Reduced Friction and Wear:

Sliding bearings are designed to minimize friction between moving parts. In heavy machinery, where components are subjected to substantial loads and harsh conditions, reducing friction is essential to prevent premature wear and damage. Sliding bearings help distribute loads evenly and provide a smooth surface for components to slide against, reducing the risk of friction-induced failures.

Increased Durability:

The robust construction and materials used in sliding bearings make them well-suited for heavy machinery applications. They can withstand the heavy loads, impacts, and vibrations commonly encountered in mining equipment. Their durability contributes to the overall reliability and longevity of the machinery.

Improved Efficiency:

Efficiency is critical in heavy machinery to maximize productivity while minimizing energy consumption. Sliding bearings contribute to improved efficiency by reducing energy losses due to friction. With lower friction, machinery components can move more freely, requiring less energy to overcome resistance.

Resistance to Contaminants:

Mining environments are often filled with dust, dirt, and debris that can infiltrate machinery components. Sliding bearings are designed to operate effectively even in contaminated conditions. Their design and materials help prevent the intrusion of contaminants, reducing the risk of premature wear and component failure.

Enhanced Load Distribution:

Heavy machinery, especially in mining, experiences dynamic and uneven loads. Sliding bearings help distribute these loads evenly across surfaces, preventing localized stress concentrations. This load distribution contributes to the machinery’s overall structural integrity and minimizes the risk of catastrophic failures.

In conclusion, sliding bearings are integral to the efficient and reliable operation of heavy machinery in industries like mining. Their ability to reduce friction, enhance durability, improve efficiency, resist contaminants, and distribute loads makes them invaluable components for ensuring the smooth functioning of mining equipment.

Signs of Wear or Damage in Sliding Bearings and Replacement Timing

Recognizing signs of wear or damage in sliding bearings is crucial for maintaining the performance and integrity of machinery and equipment. Here are the common signs to look for and the appropriate timing for replacement:

Increased Friction and Heat: If you notice higher levels of friction or heat around the bearing area, it could indicate that the bearing surfaces are experiencing excessive wear. Over time, this can lead to reduced efficiency and potentially cause further damage to the bearing and surrounding components.

Abnormal Noise: Unusual noises, such as grinding, squeaking, or knocking sounds, can indicate wear or damage within the sliding bearings. These noises are often caused by metal-to-metal contact or irregular movement of the bearing surfaces.

Uneven Wear Patterns: Inspect the bearing surfaces for uneven wear patterns, pitting, or scoring. These signs suggest that the bearing is not distributing the load properly, leading to localized damage and reduced performance.

Reduced Performance: If you notice a decline in the overall performance of the machinery or equipment, such as decreased output, slower operation, or reduced precision, it could be due to compromised sliding bearings.

Excessive Vibration: Excessive vibration can be a result of misaligned or damaged sliding bearings. Vibrations can affect the stability of the machinery and lead to premature wear of other components.

Visible Debris or Contamination: If you observe signs of debris, contaminants, or metal particles in the lubricant or around the bearing area, it could indicate wear or damage. Contaminants can accelerate wear and cause abrasive damage to the bearing surfaces.

Leakage of Lubricant: Sliding bearings often require proper lubrication to function effectively. If you notice a significant amount of lubricant leakage or seepage, it might be a sign that the bearing seals are compromised, which can lead to inadequate lubrication and accelerated wear.

Replacement Timing: It’s essential to replace sliding bearings as soon as signs of wear or damage are detected. Delaying replacement can lead to further deterioration, increased downtime, and potential damage to other components. Regular maintenance and inspections can help catch these issues early and prevent costly breakdowns.

Overall, monitoring the condition of sliding bearings through routine inspections and addressing signs of wear promptly can help ensure the longevity, efficiency, and reliability of machinery and equipment.

Advantages of Sliding Bearings Compared to Other Bearings

Sliding bearings, also known as plain bearings or journal bearings, offer several advantages compared to other types of bearings. These advantages make them suitable for specific applications where their characteristics are beneficial:

- High Load-Carrying Capacity: Sliding bearings can handle high loads due to their larger contact area and distribution of pressure, making them suitable for heavy machinery and industrial equipment.

- Low Friction: Sliding bearings operate on the principle of sliding friction, which can result in lower frictional losses and energy consumption compared to rolling element bearings.

- Simplicity: Sliding bearings have a straightforward design with fewer components, reducing complexity and potential points of failure.

- Cost-Effectiveness: The simpler design and manufacturing process of sliding bearings can lead to lower production costs and maintenance expenses.

- Shock and Vibration Absorption: Sliding bearings can dampen shocks and vibrations due to their ability to accommodate misalignments and absorb dynamic forces.

- High-Temperature Applications: Some sliding bearings are capable of operating in high-temperature environments where other types of bearings might fail.

- Self-Lubrication: Some sliding bearings are designed with self-lubricating materials, reducing the need for external lubrication and maintenance.

- Noisiness: Sliding bearings often produce less noise than rolling element bearings, which can be advantageous in noise-sensitive applications.

- Corrosion Resistance: Sliding bearings made from materials such as bronze or plastic can offer better corrosion resistance in certain environments.

- Adaptability to Dirty Environments: Sliding bearings can perform well in dirty or contaminated environments where rolling element bearings might be more prone to failure due to debris.

However, it’s important to note that sliding bearings also have limitations, such as higher frictional heat generation, potential for stick-slip behavior, and limited suitability for high-speed applications. The choice between sliding bearings and other types of bearings depends on the specific requirements of the application and the trade-offs that need to be considered.

editor by CX 2024-04-16